With the theme of "Drawing a Zero-Carbon Future through Multiple Innovations on the Same Spectrum", Cummins held the first Technology Open Day event at its new East Asia R&D center base, bringing visitors from low-carbon to zero-carbon, an immersive experience of all-round and diversified technology matrix.

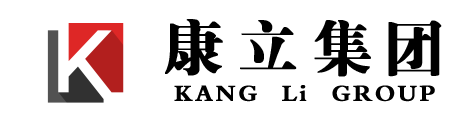

Taking this opportunity, Cummins, together with industry associations, partners and flagship customers in the logistics industry, released a customized 2.0 high-efficiency internal combustion engine technology dual platform to help complete vehicles meet the stringent requirements of the four stages of fuel. At the same time, under the joint witness of the guests, the hydrogen internal combustion engine platform, which represents a breakthrough in traditional internal combustion engine zero-carbon technology, was officially ignited in the East Asia R&D Center, demonstrating Cummins' determination and strength to accelerate the realization of the zero-carbon goal.

Breaking the constraints of resources and the environment, coping with the challenges of global climate change, achieving high-quality sustainable development, and promoting the harmonious coexistence of man and nature are the current problems facing the world. China has launched a "dual carbon" strategy to achieve carbon peaking by 2030 and carbon neutrality by 2060. The word "carbon reduction" has become one of the most popular words in all walks of life. As a global pioneer in power technology, Cummins has accumulated more than a century of internal combustion engine technology, and is also at the forefront of leading low-carbon and zero-carbon engine technology changes.Achieving zero carbon requires innovation, and innovation needs to be close to the market and customers, and requires integration. Innovation has long been engraved in the DNA of Cummins.

Co-creating the core--stepping into the era of customization 2.0

In the past nearly 50 years, Cummins has continuously upgraded its technology matrix from single product introduction to technology output, from joint venture factory construction to joint research and development, and launched products that adapt to the Chinese local market and different applications. At present, the global call for carbon reduction continues to rise, and the commercial vehicle market is facing tremendous pressure. At the same time, reducing pollutant emissions and carbon emissions has become the focus of the industry. The market is becoming more and more subdivided, which brings about the subdivision needs of model development and the differentiated needs of power solutions. Relying on its profound technical accumulation, Cummins can comprehensively consider the different needs of the local market according to different working conditions and the differentiated needs of OEMs, and provide customers with "order-based" technology development solutions, thereby helping users in efficient operation and energy saving. One step further on the road.

Shen Bin, Director of Dongfeng Commercial Vehicle Technology Center, Zhou Xingli, Vice President of Foton Motor Engineering Research Institute, Fang Huiping, Director of Shaanxi Automobile Technology Center, Zhang Yongsheng, Director of JAC Heavy Commercial Vehicle Research Institute, and customer representatives from the logistics industry and Cummins China and its joint ventures Leaders, participated in the release ceremony of "Customized 2.0 High-efficiency Internal Combustion Engine Technology Dual Platform".

The newly released customized 2.0 high-efficiency internal combustion engine technology dual platform is based on the differentiated positioning of the four-stage new fuel products of OEM customers, covering 12L and 13L, and 8 customized products, which can meet the needs of most domestic heavy commercial vehicles. The needs of different working conditions in different markets. So far, Cummins 8.5L, 10L, 12L, 13L and 15L engines can meet the requirements of the four-stage fuel consumption standard for the whole vehicle.

New technology platforms include M12/13 (Z12/13), and X12/13 (A12/13). The former is developed on the basis of the latest 15L platform released by Cummins. The 15L platform will be launched at the end of 2021. In just over a year, it has won the favor of many OEMs. The performance indicators in practical applications are very good. This kind of customized development can be The new-generation flagship heavy trucks of many OEMs provide more mainstream power; the latter is upgraded based on the mature and successful X12 platform of Cummins. The X-series products have launched more than 570,000 units in the Chinese market and have a good customer reputation and market Basically, such an upgrade is more convenient for some OEMs to quickly upgrade and iterate products, which is conducive to the continuation of vehicle performance.

Drawing a Blueprint-Starting the Hydrogen Internal Combustion Engine

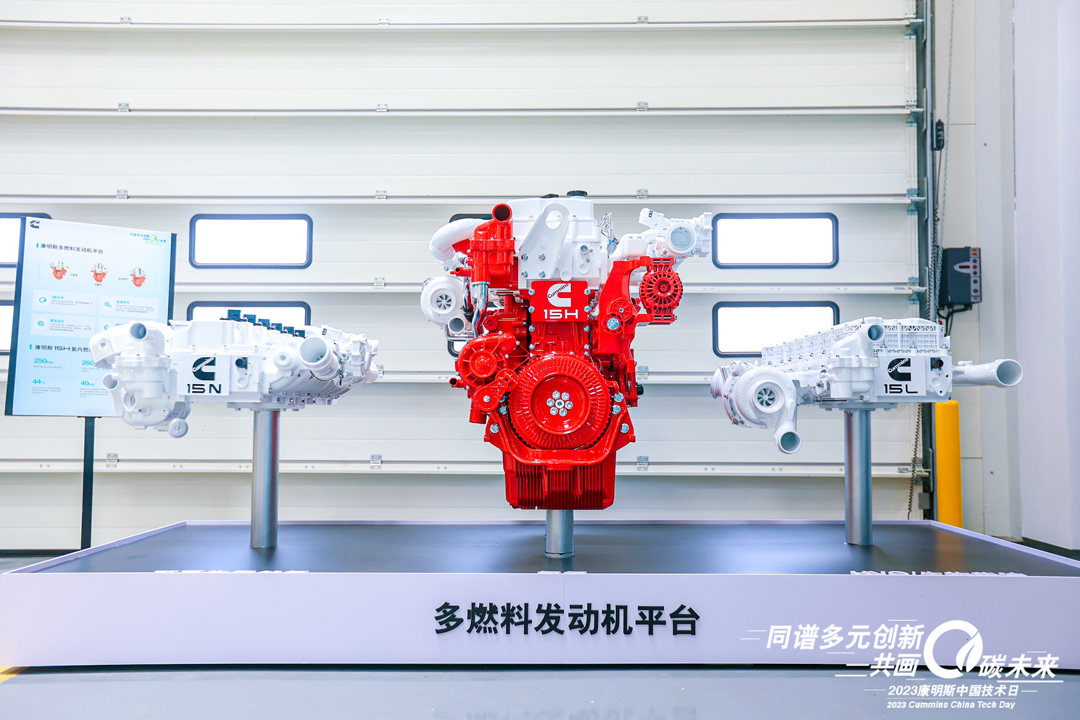

Stephen Saxby, vice president of Cummins and chief technology officer of China, emphasized at the event: "Cummins has launched the 'PLANET 2050' corporate strategy to address climate challenges, and launched the 'Destination Zero' zero-carbon goal for product carbon reduction. , is committed to reducing emissions throughout the life cycle and moving towards zero carbon through innovative energy source solutions and multi-power solutions. To achieve this goal, it needs to be implemented in stages. Before 2030, Cummins will also focus on the traditional internal combustion engine business, and develop new energy business. Hydrogen internal combustion engine, as a power solution that uses both new energy and traditional internal combustion engine technology, is a key part of the zero-carbon solution.”

At the event, Li Shaohua, deputy secretary-general of China Association of Automobile Manufacturers, and representatives from logistics industry customers such as Zhongtong and YTO attended the ignition ceremony of Cummins' new generation 15H hydrogen internal combustion engine. Cummins hydrogen internal combustion engine has planned three displacements of 15L, 10L and 6.7L. Through global collaboration, local development, custom design, and integrated optimization, direct injection and lean combustion can achieve a thermal efficiency (BTE) of 44% and an average effective pressure of 22Bar. (BMEP), and achieve zero carbon emissions.

At the same time, the hydrogen internal combustion engine is also the core of Cummins' new low-carbon and zero-carbon multi-fuel engine platform. Cummins’ new multi-fuel engine platform can use a variety of fuels, including a series of clean diesel, natural gas, hydrogen, propane and other low-carbon or zero-carbon fuels, to provide users with lower-cost Zero carbon technology path.